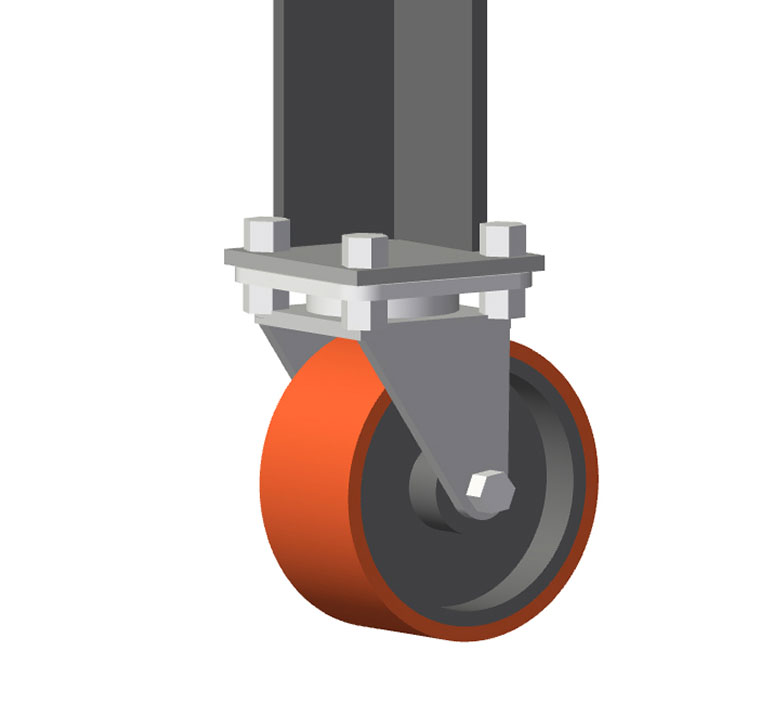

This metal welding bench or table is the ideal solution to build many of our farm welding projects. Having caster wheels, it is able to be moved around the workshop as needed.

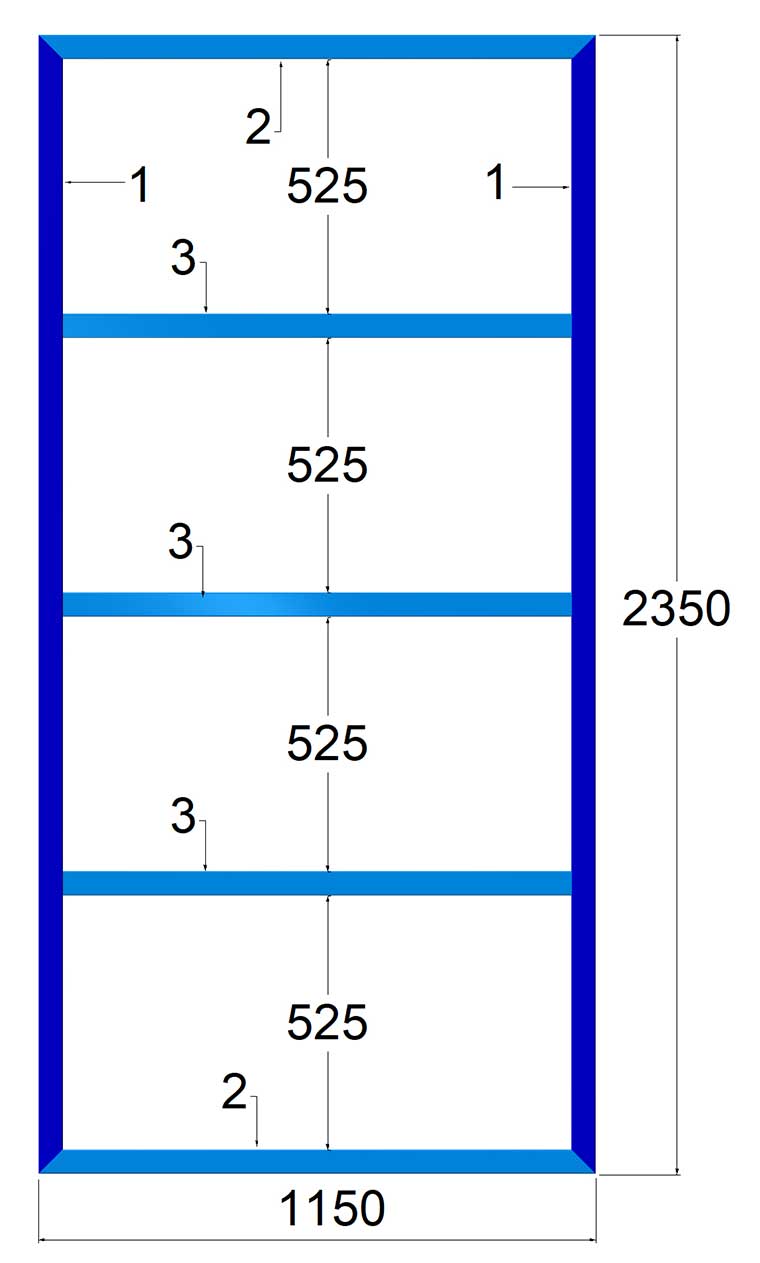

The dimensions suggested are: 2400mm long x 1200mm wide x approximately 900mm high. The steel shown in the cutting list is only a guide as you may have other material already available that you can use.