These welding trestles will be very useful when building equipment such as those featured in our plans plus has many other uses.

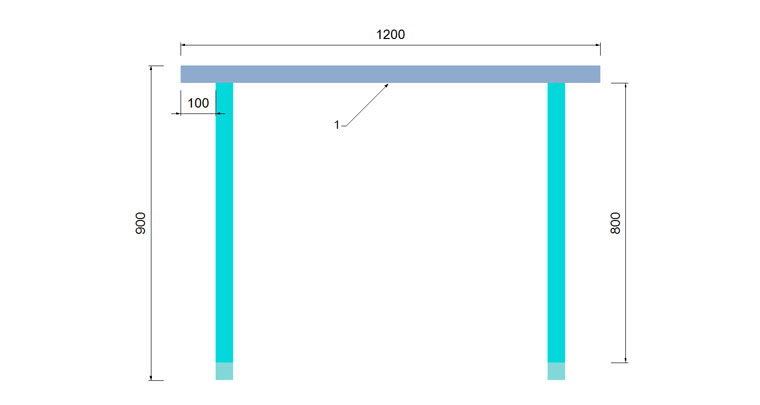

The overall height of the welding trestles as shown is 900mm but you may need to alter the height to suit your needs. This is done by simply altering the length of items numbered 2.

The steel used is 50x50x1.6mm (or 2mm) shs (square hollow section).